Your browser is no longer supported

To get the best experience with www.essentialenergy.ca, we suggest using a newer version of Internet Explorer/Edge, or using another supported browser such as Google Chrome.

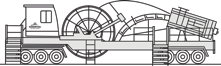

Coiled Tubing Rigs

We operate one of the largest coiled tubing fleets in Canada. Coiled tubing rigs provide completion, stimulation and work-over services on long-reach horizontal and vertical wells. Our fleet is comprised of Generation II, III and IV coiled tubing rigs, which are differentiated by their capability to service wells with varying depths and well pressures. The varied limit, capacity and coil diameter of our coiled tubing fleet make this equipment ideally suited to work in all facets of a customer’s horizontal well completion and work-over program.

Coiled tubing rigs are typically hired by an exploration and production company to be involved in the completion of a horizontal well in the following areas:

Pre-Fracturing – Coiled tubing is used to complete pre-fracturing confirmation runs and/or place the tools used to isolate a portion of the wellbore during third-party oilfield service fracture stimulation.

Fracturing – Dependent on the design of the customer’s fracturing program, coiled tubing can be used in conjunction with a third-party fracturing company and possibly other service providers to frac-thru-coil, complete annular fracturing, convey and actuate sliding-sleeve tool assemblies or perform tubing conveyed plug-and-perf operations in the well.

Post-Fracturing – Once the fracturing has been completed, coiled tubing is used to complete post-fracturing confirmation runs, clean-outs and mill-outs/drill-outs of ball & seat systems. Coiled tubing can also be used for work-overs and to convey third party instrumentation and evaluation tools to confirm the results of the fracture treatment.

Masted and conventional configurations

-

Masted Configuration

Gen II, Gen III

-

Conventional Configuration

Gen II, Gen III, Gen IV

-

- Gen II

Gen II was the first masted coiled tubing rig built on a trailer for ECWS and has been continually perfected ever since. The built-in mast eliminates the need for a crane, giving these units a small footprint and fast rig up time. For well depths <5,500m, this rig is capable of having any well up and running in the least amount of time possible. One conventional style rig is also available.

-

- Reel specs

- 2" Coil5,500 M

- 2 3/8" Coil4,500 M

- 2 5/8" Coil3,500 M

- 2 7/8" Coil2,700 M

Injector Capacity: 100,000 lbs

- Download spec sheet

-

- Gen III

The Gen III blends versatility with a deep reach and provides economic solutions. Available in both mast and conventional configurations, ECWS can tailor the right equipment package to suit any lease arrangement.

-

- Reel specs

- 2” Coil9,600 M

- 2 3/8” Coil6,600 M

- 2 5/8” Coil5,200 M

- 2 7/8” Coil4,400 M

Injector Capacity: 130,000 lbs

- Download spec sheet

-

- Gen IV

The Gen IV boasts an impressive reel capacity and carries larger and heavier coil compared to the Gen II and III. An industry leading design which is the first available to the coiled tubing market.

-

- Reel specs

- 2” Coil11,200 M

- 2 3/8” Coil8,000+ M

- 2 5/8” Coil6,700 M

- 2 7/8” Coil5,300 M

Injector Capacity: 130,000 lbs - 160,000 lbs

- Download spec sheet

Gen IV FACTS

-

- 15K

- Pressure Control

- The right tools for high pressure wells

-

- 160K lbs

- Injector Capacity

- The right tools for the deepest jobs

-

- 8+ km

- 2 3/8” Coil Capacity

- Solving technical challenges

INTRODUCING OUR NEWEST CONVENTIONAL GEN IV - RIG 2049