Your browser is no longer supported

To get the best experience with www.essentialenergy.ca, we suggest using a newer version of Internet Explorer/Edge, or using another supported browser such as Google Chrome.

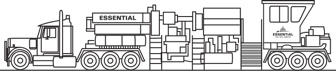

Fluid Pumpers

Coiled tubing rigs are supported by a fleet of fluid and nitrogen pumpers. Fluid pumpers maintain downhole circulation, provide ancillary acid/solvent treatments and inject friction reducers and other chemicals into the wellbore. Fluid pumpers also perform stand-alone pump-down work, pre-fracture testing and frac support work independent of the coiled tubing fleet.

-

- Twin Quintuplex

Absolute beasts, our twin quintuplex pumpers can provide high rates despite high pressure (up to 15K) applications. Ideal for standalone work, these pumpers are geared to outperform.

-

- Specs

- Horsepower2x800; 2x1,000; 2x1,500

- Pumping Pressure15,000 psi

- Download spec sheet

Support Equipment

Whether performing operations with highly technical chemical requirements, remote fuel access long surface iron rig ups, sand suspension or hanging the injector high above the swab valve, we have the necessary equipment to make it happen without calling in a third party.

-

- Chemical Addition Unit

Providing automated, closed loop and temperature controlled chemical injection directly into any pumping unit.

- Download spec sheet

-

- Iron Trailer

Carrying surface iron in varying sizes, additional hoses, fuel and anything else those extended jobs may require.

- Download spec sheet

-

- Trailered Chemical Addition Unit

The same principles as the chemical addition unit with greater storage capacity and pump flexibility. One trailer can support two pumps.

- Download spec sheet

Fluid Pumper Facts

-

- 15K

- Pumping Pressure

- Servicing the toughest formations

-

- 1500HP

- Now Available

- Packing more power in a small footprint

-

- 11

- Fluid Pumpers

- Flexibility to service growing demand